We have 8 offices around the world

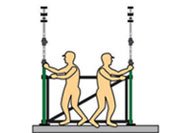

1.Stable system with 6-direction lacking restriction

2.Loading Capacity Calculation

3.No Human lifting above shoulder required

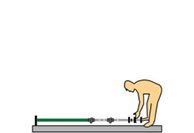

1.Only few components are required to assemble.

2.Do not require cross/lateral braces & tripods

3.Unskilled labour can easily install the system

4.Easy to transfer both horizontally and vertically

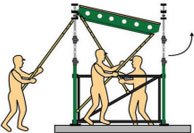

1.Can Achieve 80㎡ work done per man-day

2.4-worker team for erection, stripping & removal

3.Eariy stripping heads help to maximize the usage of panels, reduceone set panel demand

4.Compatible with other formwork systems.

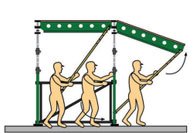

1.Shorten the Construction Period

2.Reducing the Totall Amount of Panels

3.Reducing the Labour Costs