With more than 30 years continuous hard work on Formwork and Scaffolding,QingDao Scaffolding Co.,Ltd has become Top 2 biggest manufacturers and suppliers in China in the field of Formwork and Scaffolding business .

Our company can help and support our clients all over the world with superior quality of formwork and scaffolding products .For example ,Our Green Formwork,with technology from Canada, with early stripping mechanism ,with Patents in China,USA, Australia and Malaysia,is the BEST slab formwork systems in the world in recent 15 years!Our QS Round Scaffolding,Ringlock Scaffolding systems,with Certificate from RISE Sweden,according to European standard:SS-EN12810-1,is the ONLY Chinese Scaffolding products which is BETTER than Top 1 German manufacturer!

With very strong teams of new products development,marketing and sales,engineering and management, with collaborations and supports from our various clients all over the world ,our company is always growing together with our clients steadily and rapidly.

Thanks a lot to all our team members ,clients and our suppliers .We have a very clear target :we must grow continuously and become Top 2 biggest Formwork and Scaffolding company in the world within 20 years.Your collaborations are much appreciated with thanks !

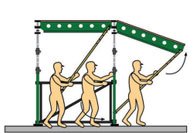

1.Stable system with 6-direction lackingestriction

2.Loading Capacity Calculation

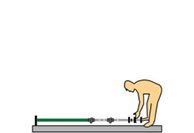

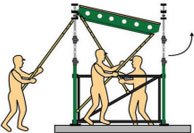

3.No Human lifting above shoulder required

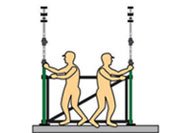

1.Only few components are required to assemble.

2.Do not require cross/lateral braces & tripods

3.Unskilled labour can easily install the system

4.Easy to transfer both horizontally and vertically

1.Can Achieve 80㎡ work done per man-day

2.4-worker team for erection, stripping & removal

3.Eariy stripping heads help to maximize the usage of panels, reduceone set panel demand

4.Compatible with other formwork systems.

1.Shorten the Construction Period

2.Reducing the Totall Amount of Panels

3.Reducing the Labour Costs

We have 8 offices around the world